Suspension Tuning of Automobiles

Abstract

Abstract

Aim:

This project seeks to simulate and analyse the behaviour of various vehicle suspension models and tune them such that the ride comfort and stability are optimized by adjusting damping coefficients.

Introduction:

Suspension is an essential aspect of vehicle dynamics. It dictates how the vehicle responds to the road conditions it experiences throughout its ride. Optimization of suspension is necessary to give the driver the best ride comfort and stability. It ensures that neither of them can compromise while catering to both of them. While springs determine how the vehicle responds to uneven surfaces, dampers play a crucial role in controlling oscillations, allowing the car to stabilize quickly after encountering road disturbances.

Before that, the study of various suspension models is necessary as it gives an overall idea of how suspensions work and the factors that can affect them.

The suspension models considered are:

-

Spring Mass Damper System: It consists of a mass supported by the suspension model, which consists of a spring and a damper.

-

Quarter Car Model: It represents a simplified model of one wheel and the corresponding suspension system.

-

Half Car Model: It represents the front and rear suspensions of the vehicle.

-

Full Car Model: It represents the dynamics of all four wheels and their suspension system.

In this project, Simulink models of these models are made for the study of their responses to the road inputs. Optimization is done by plotting a comfort-stability plot on MATLAB for the optimum parameters to ensure the tuning of the suspension. Realistic values are used to gain real-life results.

Softwares used:

-

SIMULINK (for simulating the model and analysing the suspension response to the road input).

-

MATLAB (for plotting the comfort-stability plots and finding the optimum values for tuning).

Suspension Models:

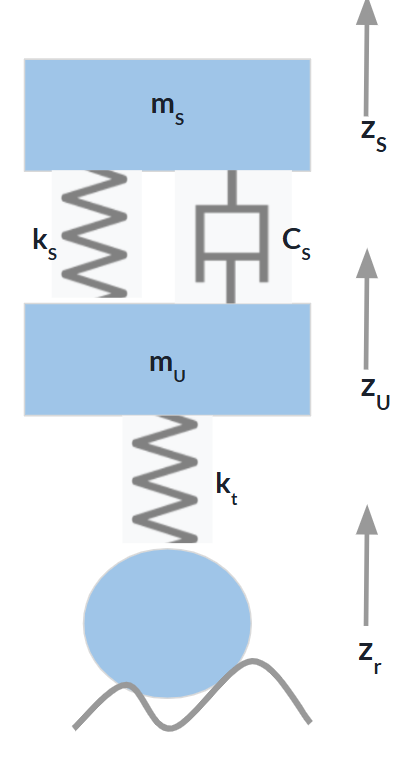

Spring Mass Damper System:

It is a system that consists of a block of mass ‘m’, supported by a spring and a damper, as shown in the below figure.

Below is the SIMULINK model with the simulation responses:

Quarter Car Model:

It is a 1/4th model of a car, consisting of the spring mass damper system, with the tyre being the only addition. So, it is basically an extension of the spring mass damper system.

Here, we are considering a single tire of a car with a spring and a damper to derive the equation for the acceleration of the sprung and the unsprung masses of the vehicle. This model has two degrees of freedom.

The sprung masses in a car are the body, frame, internal components, passengers, and cargo.

The unsprung masses are the wheels, wheel bearings, brake rotors, callipers, and/or continuous tracks.

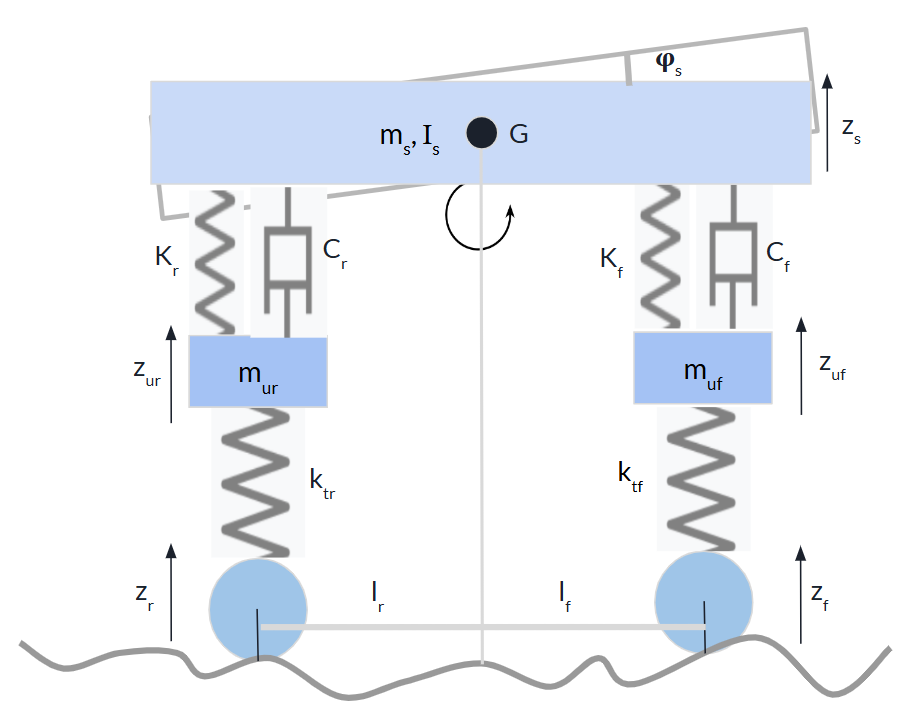

Half Car Model:

The Half Car Model is the extension of the Quarter Car Model, where a simplified longitudinal representation of a vehicle is considered for analysis of the dynamic response due to road excitations. This model incorporates both the front and rear suspension systems (one axle), which include the sprung mass (vehicle body, denoted as ms) and the unsprung masses (muf and mur) associated with the front and rear wheels. Four degrees of freedom include the vertical motions of two unsprung masses and combined sprung mass along with the pitch motion of the body.

The unsprung masses are supported by tire springs with stiffness coefficients ktf and ktr. Suspension systems are modelled with linear springs (Kf and Kr) and viscous dampers (Cf and Cr). Road excitations at the front and rear wheels, Zf and Zr, cause vertical displacements and rotations of the masses. These road inputs represent uneven surfaces, such as bumps or potholes.

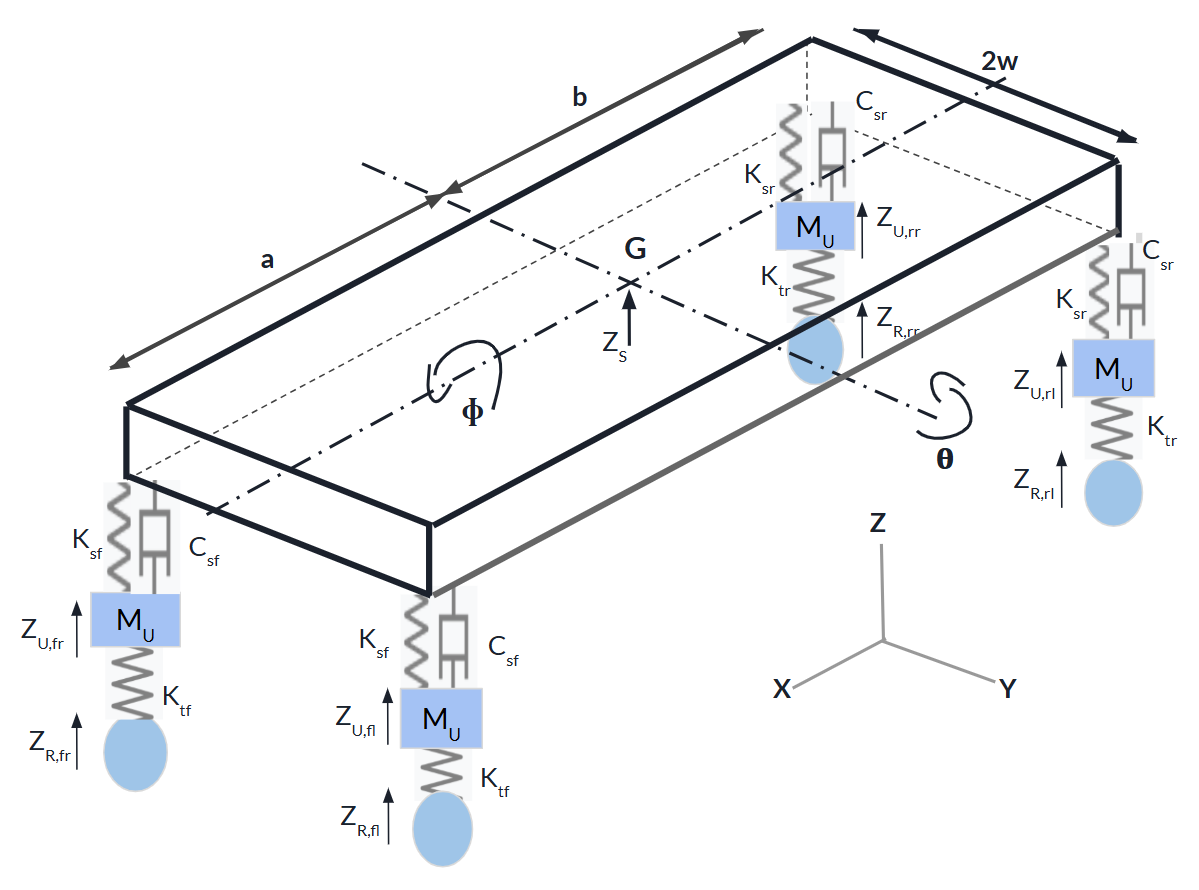

Full Car Model:

A full car model closely resembles an actual car. It is an extension of the half car, with two more tires on either side. It has a sprung mass Ms, and four unsprung masses MU,fl, MU,fr, MU,rl and MU,rr linked to it at four corners via the suspension springs and dampers. This model has 7 degrees of freedom as it involves Roll Motion (Rotation about Longitudinal Axis).

Tuning:

Ride comfort refers to the ability of a suspension system to absorb the road, irregularities, vibrations and shocks, allowing a smooth ride for the passengers.

Stability refers to the vehicle's ability to maintain traction, control, and balance during dynamic conditions, such as cornering, accelerating, or braking.

For comfort-oriented cars, smooth, softer springs and mild dampers are used. However, handling and stability are compromised.

Structural springs and moderate dampers are used for stability-oriented cars. However, comfort is compromised (used in high-performance vehicles, such as sports cars).

In this project, we have tuned the quarter car models of a Normal car and a BMW, and the half car model of a BMW.

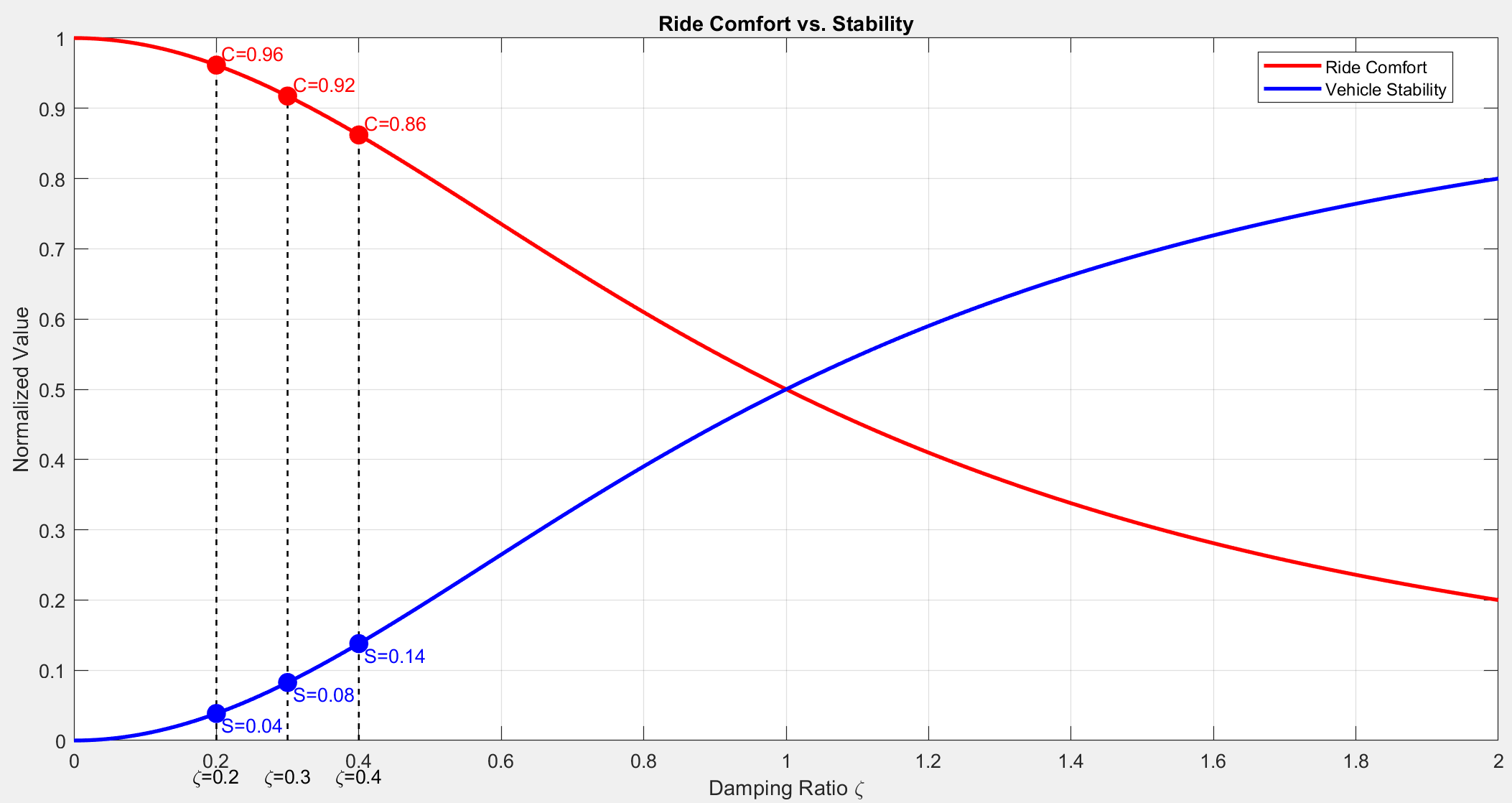

For tuning of the quarter car models, plot of comfort and stability along the y-axis and damping ratio (𝛇) along the x-axis were made for a normal car and a BMW, using MATLAB. The values of the damping ratios usually implemented by manufacturers were obtained to calculate the damping coefficients (Cs) for both the vehicles. For each vehicle (fixed mass and tire stiffnesses), the damping ratio was varied from 0 to 2, and the corresponding values of stability and comfort were calculated to obtain the plots. The settling times were also obtained for the tuned values.

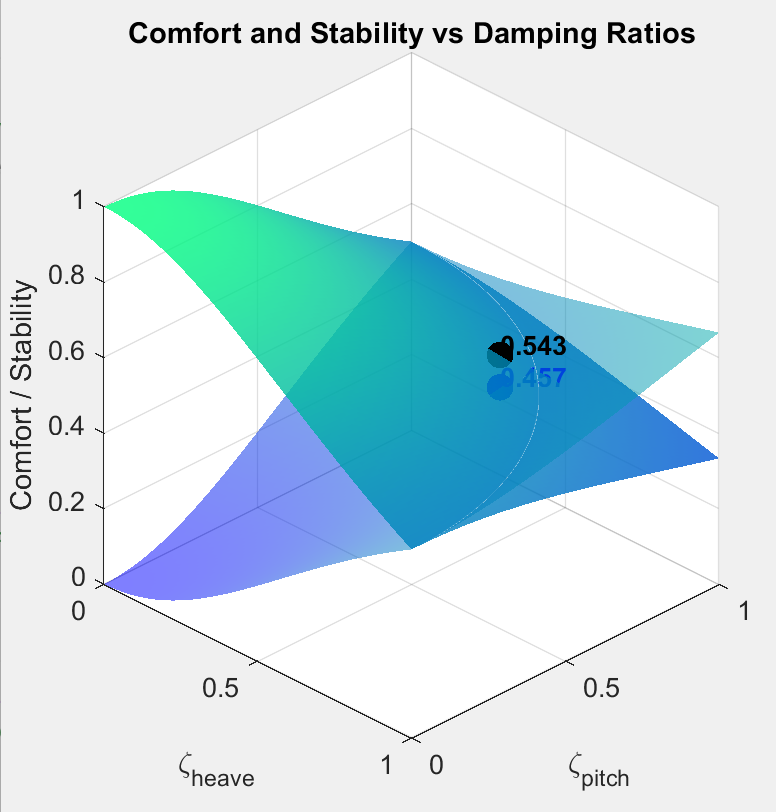

For tuning of the half-car model of BMW, plot of comfort and stability along the z-axis and damping ratios (𝛇heave and 𝛇pitch) along the x-axis and y-axis, respectively, was made using MATLAB. This was done to visualise the variation of comfort and stability with damping ratios. The values of the damping ratios usually implemented by manufacturers were obtained to calculate the comfort and stability at this point. The damping ratios were varied from 0 to 1, and the corresponding values of stability and comfort were calculated to obtain the plots.

Results:

Thus, from the plots, it is clear that as damping ratios increase, comfort decreases, but stability increases. At any point, the damping coefficient can be altered for ease of analysis for various types of systems as well as for tuning.

Simulink Models:

https://drive.google.com/drive/folders/1JoUYMziT2df04U3iyAnbWx5J1AUvPMpl?usp=sharing

Future Scope:

Currently, suspension tunings of the quarter and half car models of the two vehicles are done. Tuning of the full car model can be done in a similar way to obtain more accurate results.

The methodology is the same, the only difference being the parameters involved with the 7 degrees of freedom.

References:

https://drive.google.com/drive/folders/1KC-xdHsS95rjG7wNLk5Goe3G0kSfCKQ_?usp=drive_link

Acknowledgement:

As executive members of IEEE NITK, we are incredibly grateful for the opportunity to learn and work on this project. We extend our heartfelt thanks to IEEE for supporting us throughout the course of this project.

Conclusion:

This project has provided valuable insights into the role and importance of vehicle suspension systems in enhancing ride comfort and stability. Through this study, we explored the various parameters that affect suspension performance, such as spring constant, tire stiffness, and damping coefficient.

We examined the trade-offs involved in tuning suspensions, especially in terms of achieving a balance between comfort and stability through optimisation of the parameters involved in various suspension models.

Simulations, modelling, and reference studies illustrated how slight variations in suspension parameters can significantly affect the overall outcomes. This is evident from our comfort-stability plots.

In conclusion, suspension tuning is not just a mechanical adjustment but also a mathematical optimization of the parameters involved in various suspension models, and each suspension model has different degrees of freedom and, therefore, different complexities. Proper tuning ensures not only driver and passenger comfort but also overall performance, making it a critical component in automotive engineering. This project has enriched our understanding of suspension systems and laid a strong foundation for further research and development in this domain.

Report Information

Report Details

Created: April 11, 2025, 10:54 p.m.

Approved by: Guddati Sri Sai Akhil [Piston]

Approval date: None

Report Details

Created: April 11, 2025, 10:54 p.m.

Approved by: Guddati Sri Sai Akhil [Piston]

Approval date: None